The battery drive auto trackless transfer cart has the advantage of moving the entire length of the manufacturing facility, where dies that are moved by cranes are limited to the distance of the crane travel, or must be transferred from crane bay to crane bay. Our standard heavy duty design is controlled by a hand held push button controller with small turning radius.

The heavy load battery powered transfer vehicle is made up of the battery as the power source of the series of flat cars. It supplies power to the flat car. The DC current flows into the electric box, and the electric box is supplied to the operating system and the motor. The control unit or the remote control controls the motor.

Workshop Low Flatbed Battery Transfer Carriage Lifting Auto Control. Material Transfer Cart. 1-30t Heavy Load Steerable Transfer Cart Customization Remote Control. Battery Powered ISO Material Transfer Cart 20m/Min. CE 30t Die Transfer Cart Customization Color Battery Powered. Low Voltage Rail Operated 80t Electric Transfer Trolley

The heavy-duty battery-powered transfer vehicle is composed of batteries and is the power source for a series of flatbed vehicles. It powers the flatbed truck. The direct current flows into the distribution box and supplies the distribution box to the operating system and the motor.

Jan 08, 2022 · Quality Trackless Transfer Trolley & Rail Transfer Trolley Electric Battery 30 Tons Die Transfer Cart Industry Metallurgy Height 650mm Radio Control 35T Heavy Duty Transport Trolley , Multi Function Electric Flat Car Wireless Ladle Transfer Trolley , Heavy Duty Electric Transfer Cart With Weighing Scale Industrial Carts | Heavy Duty Utility Carts with Wheels Heavy duty 14 gauge steel 2″ x 2

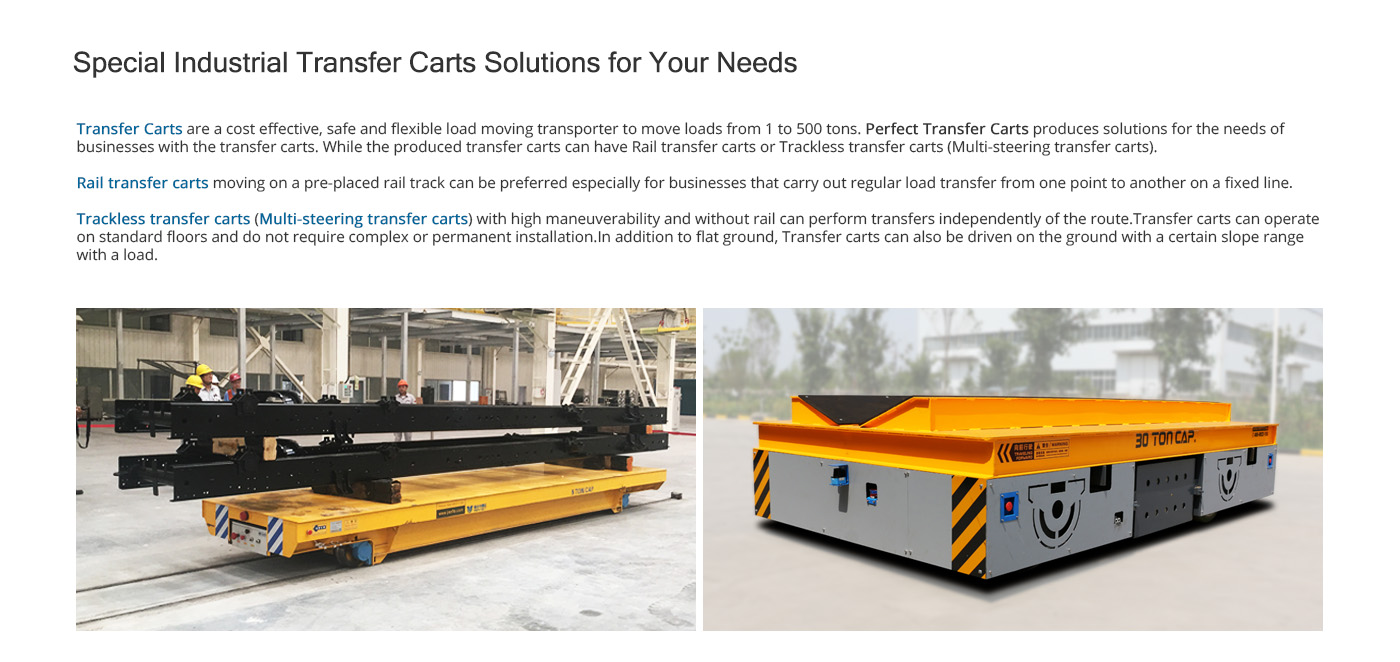

Transfer cart is a kind of cost-effective, safe and flexible material handling cart widelyCustom in fabrication shops, warehouses, metallurgical plants, etc. for load transportation. It can also cooperate with overhead and Perfect Industrial Transfer Carts in the workshop to transport heavy loads across the bridge.

Introduction: Heavy duty auto shuttle coil carrier Agv transport system permit the 380V alternating current get in the electric control system directly and then drive the motor to make it start, stop, move forward and move backward. The cable lies in the middle of the two rails and the working voltage is safe 36V.

Industrial Heavy Load Rail Turntable Transfer Cart For Plant. The industrial turntable is mainlyCustom for the turning of railway flat cars in industrial workshops. The precise rotation angle isCustom to make the flat cars run in different directions, which can realize various direction changes.

China 20 Tons Heavy Duty Motorized Motor Drive Flat Bed Die Mold Trackless Transfer Cart in Heavy Industry, Find details about China Transfer Cart, Transfer Truck from 20 Tons Heavy Duty Motorized Motor Drive Flat Bed Die Mold Trackless Transfer Cart in Heavy Industry - Tianjin Langyu Robot Co., Perfect Transfer Cart.

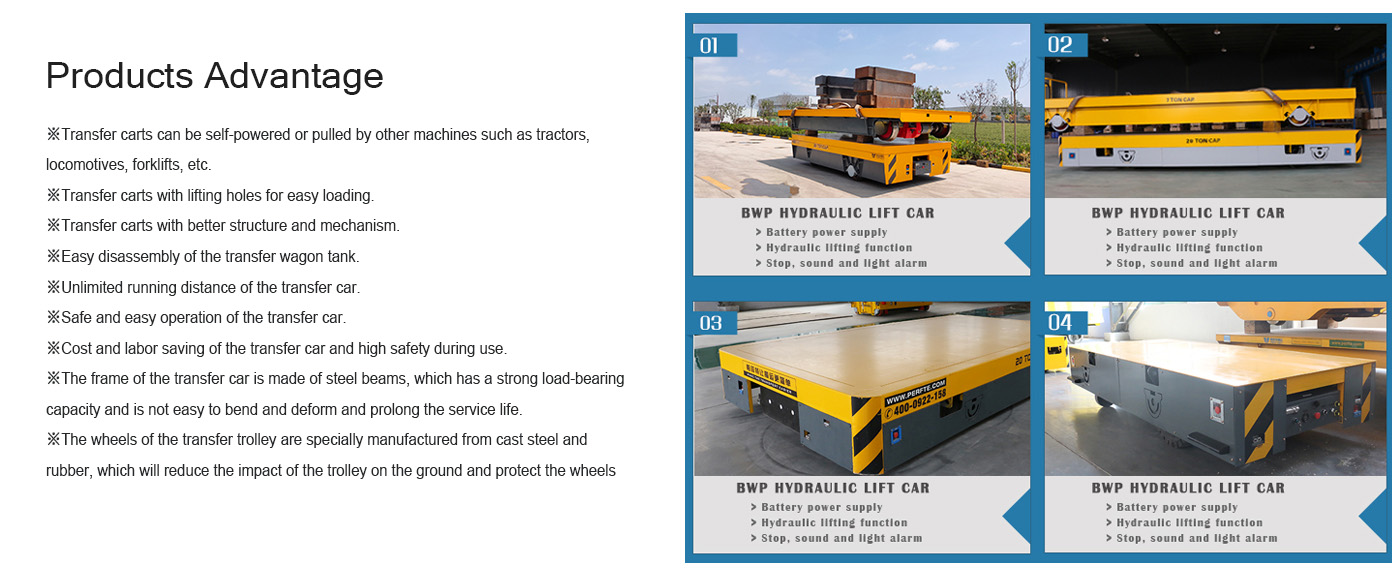

Operating with high efficiency, Perfect transfer carts provide businesses with high profits in terms of time and personnel. Supply with battery or non-contact (wireless) energy transfer systems Up to 1000 tons capacity Auto / manuel control High maneuverability Safety laser scanner Synchronous working feature for heavy loads .

Perfect Heavy Load transfer cart. Founded in 2003, Our company covers an area of 30,000 square meters and annual output is 500sets motorized transfer trolleys. With oversea market extension, we enlarged our plant and purchased many equipments such as plasma CNC cutting machine, advance welding facility etc.

The heavy load battery-powered transfer cart is made up of the battery as the power source of the series of flat cars. It supplies power to the flat transfer cart. The DC current flows into the electric box, and the electric box is supplied to the operating system and the motor. The control unit or the remote control controls the motor.

This versatile transfer cart (shown above) from Electro Kinetic Technologies was originally designed to carry loads of 40-ft. stainless steel pipe. Specifications. KEY FEATURES. Payload capacities up to 40,000 lbs. Smaller footprint and less training required than forklifts. 360-degree control. Ergonomic control station.

Introduction: Heavy duty auto shuttle coil carrier Agv transport system permit the 380V alternating current get in the electric control system directly and then drive the motor to make it start, stop, move forward and move backward. The cable lies in the middle of the two rails and the working voltage is safe 36V.

China Foundry Parts Injection Mold Die Rail Transfer Cart with Limited Switch. The automated guided carts adopts dual-core dual control system. The power drive adopts precision differential drive. The original AGV curve autoally triggers 4-wheel follow-up technology to improve the site adaptability and reduce the turning radius.