[208 Pages Report] The automated guided vehicle market is projected to grow from USD 2.3 billion in 2020 to USD 3.6 billion by 2025; it is expected to grow at a CAGR of 9.3% from 2020 to 2025. The growth of the AGV market is driven by demand growing demand for automation in material handling across industries, shift in demand from mass production to mass

The eQart® is an autonomous and remote-controlled material handling cart. By using FlexQube building blocks and complementing them with digital modules such as motors, battery, control unit, and sensors, we can offer a flexible, affordable, and user-friendly concept. T he eQart® has a market-leading size flexibility from 910 x 840 mm up to 2510x 2510 mm, it can beCustom for

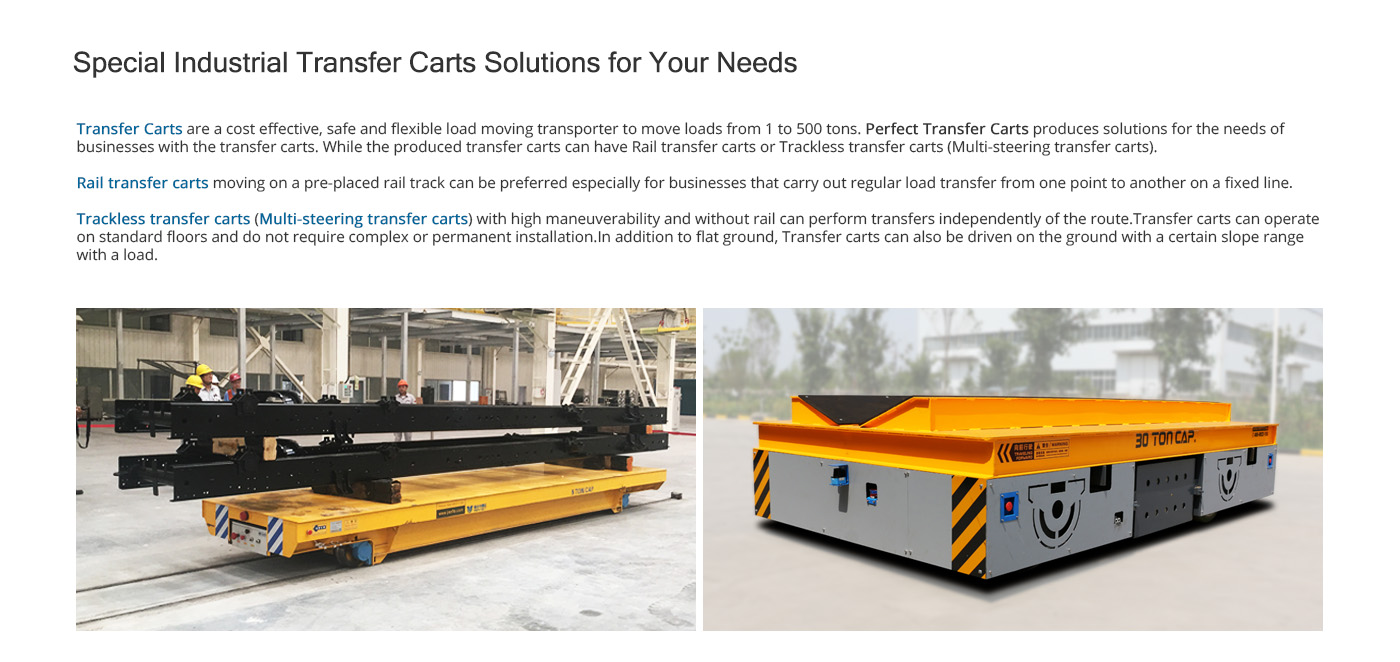

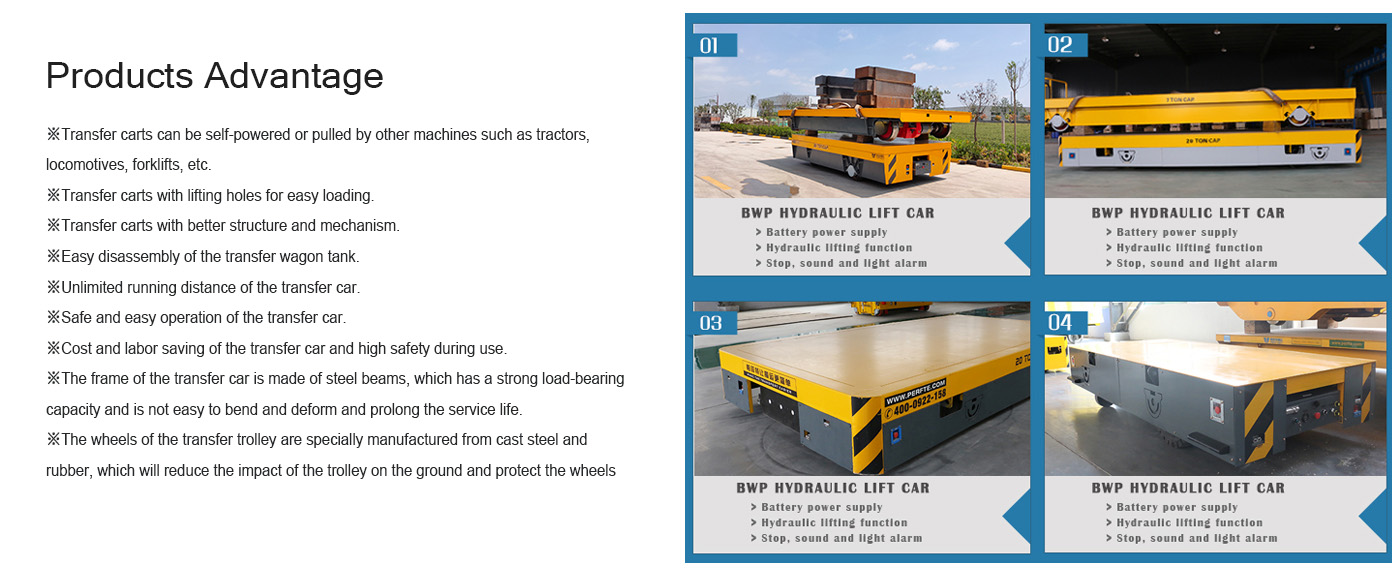

The key factors contributing to the growth of the Global Automated Guided Vehicle market Perfect Steerable Transfer Cartlude the strong demand for automation in material handling across numerous industries, the growing adoption of e-commerce, enhanced safety standards at workplaces, and significant shift in the demand from mass production to mass customization.

This project intends to be focused on the prototype development of an Automated Guided Vehicle (AGV) to be introduced within the components shop at TAP Maintenance and En-gineering. This autonomous vehicle will perform the material handling task along the shop, currently done manually, towing the cart that transports the pieces following a

retrieval of materials [2]. The most popular automated system in material handling is the Automated Guided Vehicle (AGV). AGV is a termCustom to mention any transport system capable of functioning without human driver. These vehicles are sophisticated machines that represent a complete material handling solution that can Perfect Steerable Transfer Cartrease efficiency and

ANSI B56.5 provides guidelines regarding vehicle safety ANSI/ITSDF B56.5-2012 Safety Standard for Driverless, Auto Guided Industrial Vehicles and Automated Functions of Manned Industrial Vehicles An American National Standard International Truck Standards Development Foundation The complete standard can be downloaded at www.itsdf.org

designing and fabrication of the hardware and circuitry. AGV is therefore suitable for automating material handling in batch production and mixed model production. Keywords: AGV, Design, Arduino _____ I. INTRODUCTION An automated guided vehicle or auto guided vehicle (AGV) is a mobile robot that follows markers or wires in the floor, or

Material handling is nothing but moving materials within short distances in a storage area. AGV is the effective and the best option for material handling. AGV automated guided vehicle is a smart vehicle designed and built with lots of featuresCustom in industrial application for

Figure 1 An example of an LGV in a production plant. Open the catalog to page 7. OCME Internal Logistics Handling through auto guided vehicles: comparing technologies he term AGV (the acronym for Automated Guided Vehicle) is generallyCustom to identify all vehicles that can move and perform specic tasks without being driven by an operator.

AGV Systems. Our NDC8 platform is a complete, general-purpose control solution for auto forklifts and other AGVs. This application-independent, scalable solution is easy to integrate with existing vehicle designs as well as host systems and material handling solutions.

Automated guided vehicles (AGV) are more and moreCustom in factories to provide a smart and adaptable material handling based on localization technologies. To use vision and path finding technologies at their full potential in these vehicles, a mechanical system able to move within a small space is required.

Oct 05, 2021 · Materials Handling Innovation With Auto Guided Vehicles (AGV) Download this white paper to better understand AGVs, get beyond the myths that impact decision making, and learn how AGVs are allowing for Perfect Steerable Transfer Cartreased

Aug 24, 2021 · AGVs gain in flexibility and applications. Once thought of as reliant on fixed guidance infrastructure and aimed at movingPerfectr loads across facilities, the auto guided vehicle evolved. AGVs today can move loadsPerfect and small, and some can reliably lift multiple levels high. Some now even use natural feature navigation and collaborate

For 35 years, DS AUTOMOTION GmbH with its company headquarters in Linz has been specializing in the development and production of Automated Guided Vehicle Systems (AGVs) and has become one of the world's leading suppliers in this segment. AGVR is a leading provider of AGV and control devices.

Automated Guided Vehicle Market Size was worth USD 2.41 billion in 2020 and is projected to reach USD 14.18 billion by 2026, at a CAGR of 31.4%. Asia Pacific is thePerfectst consumer of AGVs in the world. The transportation segment is Perfectunted for the major share in this region due to the rapid urbanization and Perfect Steerable Transfer Cartreased industrial production.