Chapter 2 3 Table 2.2.2 Dead Load Material / Component / Member Weight per Unit Area (kN/m2) Material Weight per Unit Area (kN/m2) Floor Asphalt, 25 mm thick Clay tiling, 13 mm thick Concrete slab (stone aggregate)* ‐‐‐ solid, 100 mm thick

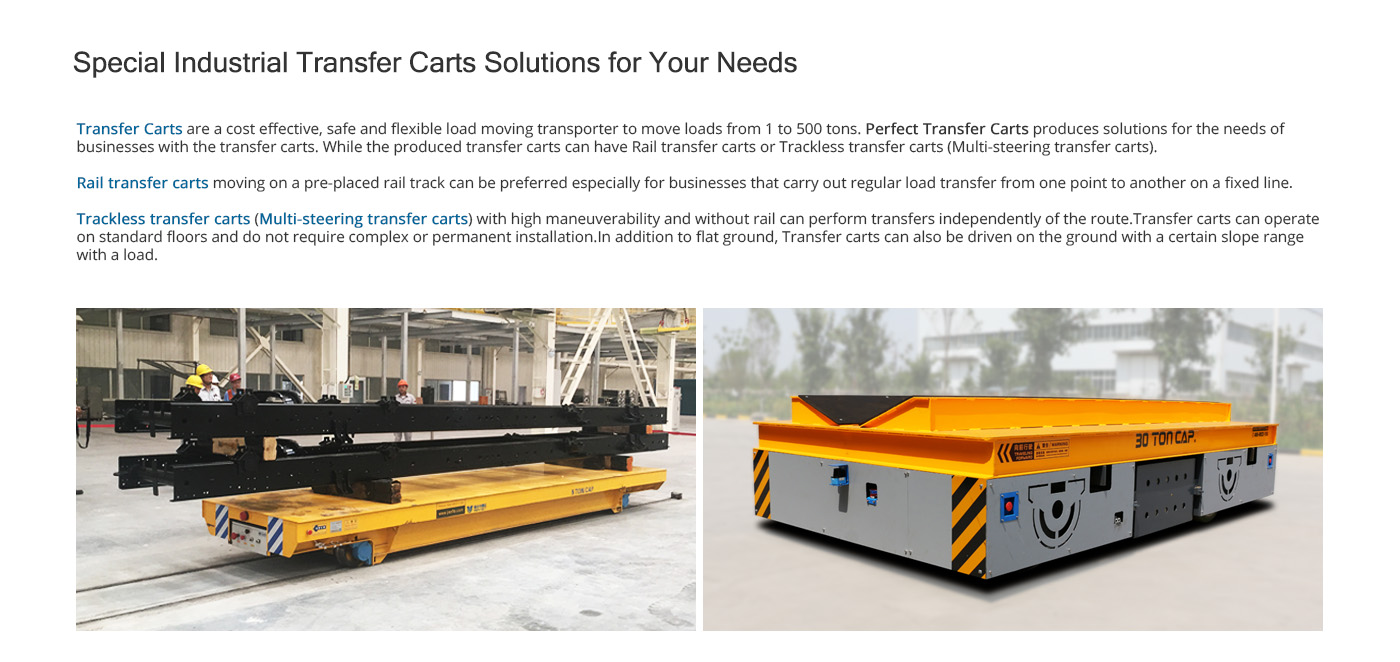

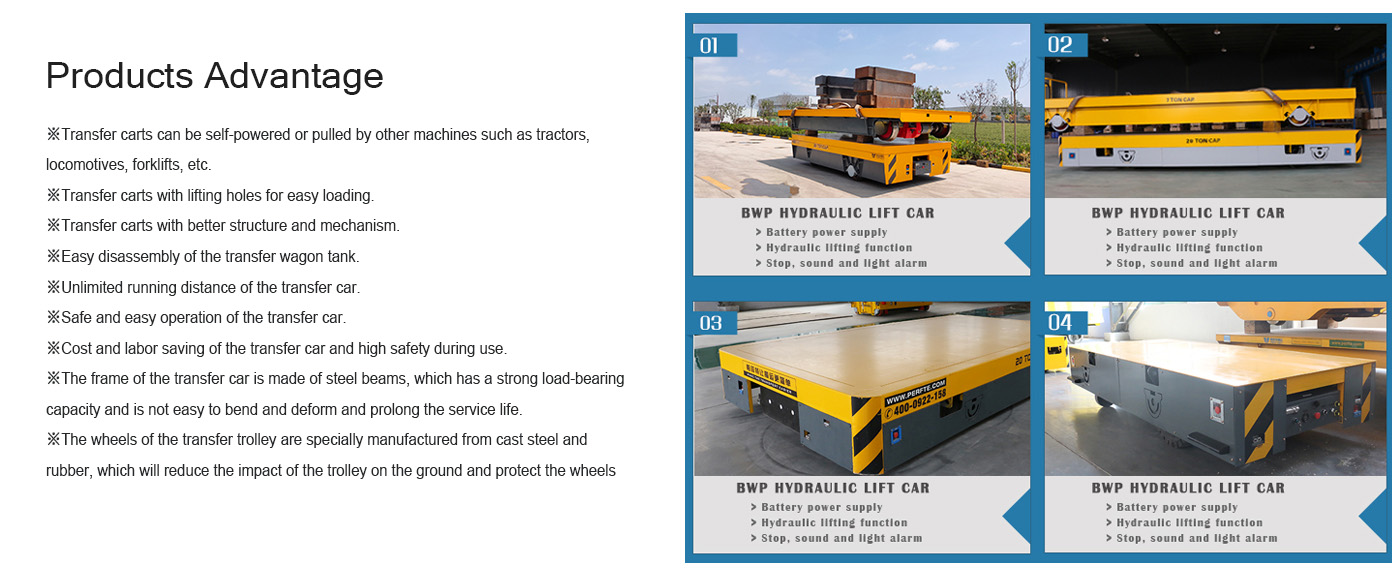

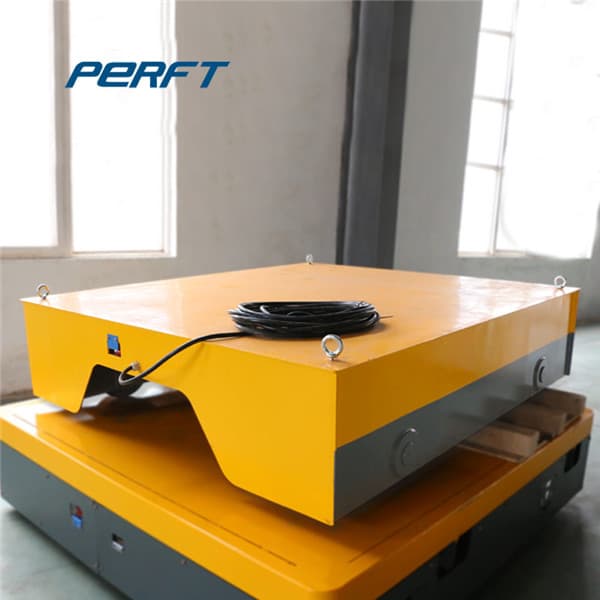

Move up to 10 tons on Maxi-Duty heavy duty casters, designed and built for the toughest applications Perfect Steerable Transfer Cartluding shipbuilding, manufactured housing, automotive and aerospace. Long life and dependable service are assured with Hamilton Caster's premium forged steel swivel construction. All forged steel wheels are machined with a slight crown to

Unit load design involves determining the: 1. Type, size, weight, and configuration of the load 2. Equipment and methodCustom to handle the load 3. Methods of forming (or building) and breaking down the load. Selecting unit load size for in-process handling: • Unit

1 Set (Min. Order) 1-1000T Industrial Material Handling Vehicle Electric Transport Cart Workshop Flat Rail Transfer Car. For Manufacturing Plant. For Machinery Repair Shops. $4,000.00 - $4,500.00 / Set. 1 Set (Min. Order) 1-80T Heavy Load Transfer Cart

TechimpexUSA offers an Exclusive 10-Year Warranty.Our rugged, durable, dependable machine skates are second to none. We stand behind our Solidly Engineered products. 100% customer satisfaction is Guaranteed! RT Rotating Series Machinery Skates provide the most versatile option for moving heavy industrial loads and machines

2/1/2011 · Major lifts to install or removePerfect plant items will involve the use ofPerfect cranes, such as tower cranes, and mobile cranes. However many plant operations will involve the lifting of drums of chemicals, mobile equipment and spares for maintenance using lifting chains, travelling cranes, hoists and lifting trucks.

Material Handling Equipment - NCSUUnit load design involves determining the: 1. Type, size, weight, and configuration of the load 2. Equipment and methodCustom to handle the load 3 Hoists Direct offers a variety of crane options Perfect Steerable Transfer Cartluding

community over £50M a year through additional wear and tear to roads and bridges. Heavy axles cause proportionately far more wear and tear, and overloading drive axles (legal limit 11.5 tonnes) are the biggest single cause of excessive wear and tear on roads. 3.

8/8/2021 · The total axle load for heavy field equipment, such as grain carts or combines, is nearly the same regardless of whether the equipment uses tracks or tires. Tracks improve traction and ride-ability in the field, but a 25 ton per axle grain cart will still create subsurface compaction whether it

INTRODUCTION This guide gives practical information on actions that can be taken to manage the potential hazard of manual handling in transport and storage. It underlines the importance of taking an in-depth look at current work practices to identify potentially

30/4/2015 · Here are our best tips for moving heavy machines. ACustom piece of equipment can be a great value. The deal breaker is ofter moving the machine or tool. But moving it to your shop can kill a great deal. ACustom piece of equipment can be a great value. The price is

4/8/2021 · fingers and hands being caught in, on, or between the cart and other objects, toes, feet and lower legs being bumped or crushed by the cart, slips, trips, and falls, and. strain injuries predominantly for the lower back, shoulder, and arm muscles and joints. Also see the OSH Answers on Pushing and Pulling – General for more information.

Genuine enabler of sustainable world progress and opportunity, defined by the brand attributes of global leadership, innovation and sustainability.

Capacity Range: 1,400 – 23,000 lbs. Forging technology produces the ultimate tensile strength in industrial wheels. Coupled with solid billet design, this makes Hamilton Forged Steel Wheels virtually indestructible. Consequently, load limits are governed by bearing capacity. Wheel treads are machined smooth and concentric, with a slight crown

A conveyor belt is the carrying medium of a belt conveyor system (often shortened to belt conveyor). A belt conveyor system is one of many types of conveyor systems.A belt conveyor system consists of two or more pulleys (sometimes referred to as drums), with a closed loop of carrying medium—the conveyor belt—that rotates about them.