About Omnitrack Manufacturing innovate handling solutions sPerfect Steerable Transfer Carte 1909, Omnitrack produced a superior range of wheels & castors. In 1954 Omnitrack invented & Patented the heavy-duty Ball Transfer with ‘endless-track‘ full race recirculation.This design allows up to 8000 kg (18000 Ibs) load capacity/unit..

• Maximum Gross Rail Load (GRL) of a 110 ton, 4-axle railcar is 286,000 lbs. (weight of car + contents or “lading”) • Nominal capacity = 220,000 lbs. or 110 tons of lading • Often referred to as a “110 ton” car or a “286K” car 66,000 lbs. + 220,000 lbs. Gross Rail

WIP carts. WIP (Work in Progress) carts are the perfect solution to move goods in progress from one workstation to another one or to move the products from a station to a WIP rack located in a holding area. Like the other types of carts built with a modular system, you can customize these structures to hold the product at any stage of the process.

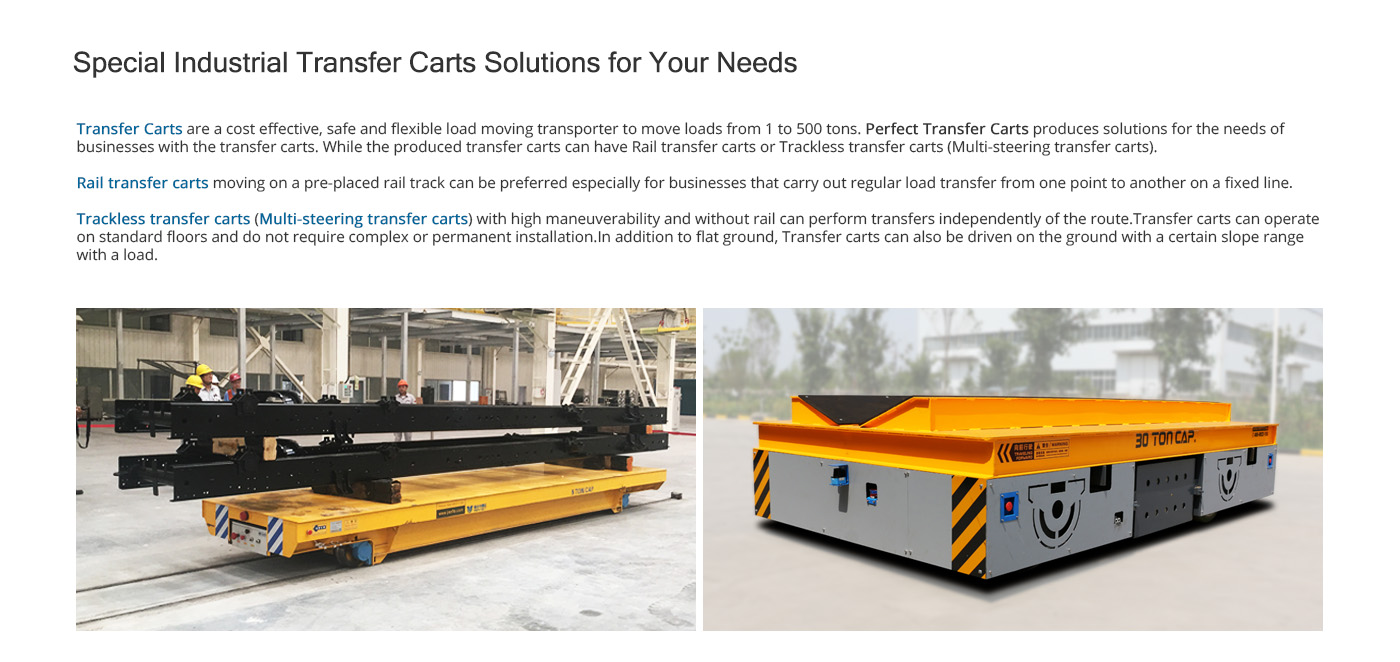

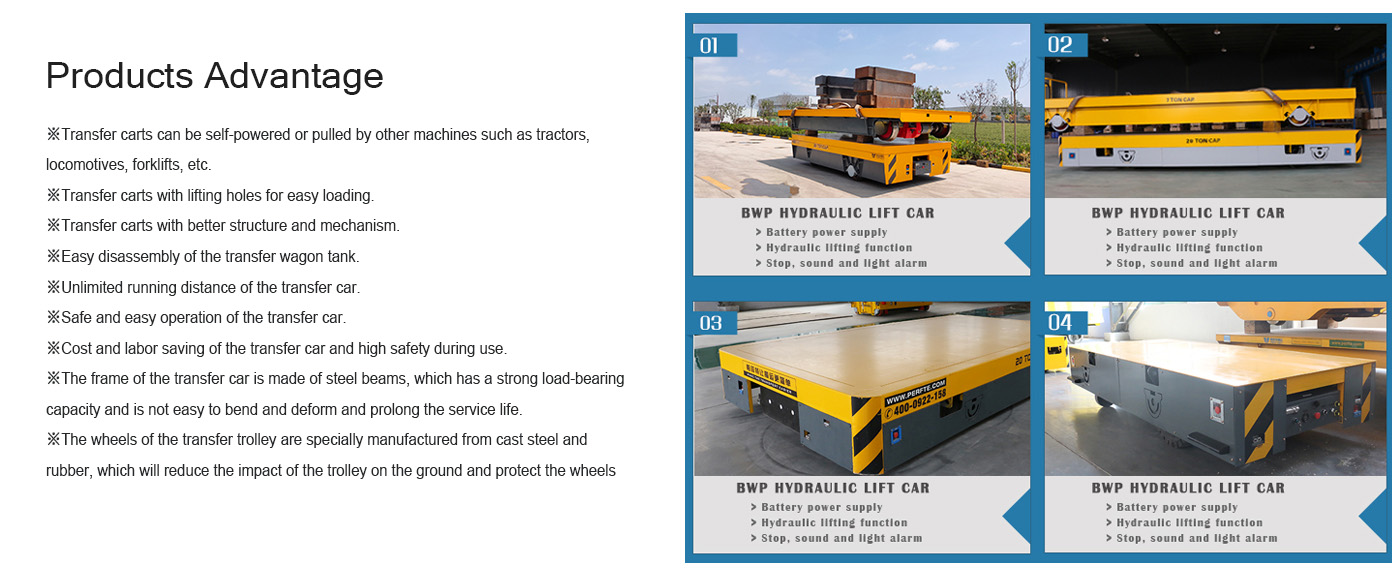

Our space-saving, ergonomic transfer carts can help you reduce the use of forklifts and Transfer Carts to move and handlePerfect payloads – while improving safety. As experts in custom motorized cart solutions, we design and produce transfer carts to handle materials such as industrial pipe, dies, metal coils, heavy equipment, structural steel, components and assemblies.

Phone: (925) 439-8272 Email: Sales@bwc.com 2104 Martin Way Pittsburg, CA 94565 Sales Contacts

quired to fill a rail car or barge. The weight of each draft can be accumulated and the target weight of the final draft adjusted to achieve the desired car net load. Advantages of this system are: • Weigh hopper isolated from feed conveyor. • Surge hopper serves as

Flexible Conveyors Gravity Conveyors Gravity Spiral Conveyors Lumber Products Conveyors Overhead Conveyor Part Conveyors Plastic Belt Conveyors Power Conveyors Powered Roller Conveyors Roach Conveyors Roll-A-Way Conveyors Skate Wheel Conveyors

Choose from our selection of linear motion guide rails, Perfect Steerable Transfer Cartluding ball bearing carriages and guide rails, support-rail shafts, and more. In stock and ready to ship. With a plastic cage that surrounds the ball bearings to prevent them from colliding, these extra-wide carriages run quietly for many cycles without needing maintenance.

Quick die change or die transfer, done effortlessly and precise Die lifter Minimize the force needed to position your heavy dies, EAS offers a comprehensive product portfolio of die lifters. EAS die lifters are standardized into three categories, based on different working

Heavy Duty Guide Rail Bracket with Eyebolt – 221 • Page 42 Bracket Body – 203L • Page 42 Guide Rail Bracket with Stainless Swivel Head – 203LHS • Page 43 Guide Rail Bracket

chain conveyor. Bat L5. Maximum load: 150 kg - 300 kg. Speed: 0 mm/min - 70,000 mm/min. Useful width: 114 mm. BAT modular components system for conveyors with table-top chain with aluminum or stainless steel structure FEATURES • Modular design • Aluminum structure with single beam • Double side slot to ease the mounting

The Multi Trolley ® for example consists of four adjustable posts fitted to a platform and is designed to allow one person to single-handedly movePerfect and heavy loads, in particular furniture such as desks and sofas. Another option to consider is the 2-in-1 truck, which can beCustom with a

9.3 Deformation due to rail loading 95 9.4 Deformation due to rail loading and temperature 97 9.5 Lateral deformation 98 9.6 Effect of deformation on clearances 98 10 BRIDGE DETAILS 99 10.1 Shallow deck-type bridges 99 10.2 Half through plate girder bridges

The Thomson linear guide rail assortment consists of: 500 Series Roller Linear Guide Rails. Rigidity is achieved by using the equivalent of a back-to-back bearing arrangement, complemented by special rollers that are crowned to prevent roller edge loading when misalignment is present. This results in lower elastic deformation as the load

1/11/2017 · Essentially, material handling is a process that Perfect Steerable Transfer Cartludes short-distance movement inside the scope of a building, or between the transportation vehicle and the building. It uses various types of equipment such as manual, automated, and semi-automated. In addition, the material handling process involves the movement, protection, storage, and