Welcome to AGVE. The AGVE Group is a leading provider of Automated Guided Vehicles (AGVs) or Auto Guided Vehicles and control devices, having 60 dedicated employees worldwide working on Automated Guided Vehicle automation.With in-house design and manufacturing, we have sold more than 2.500 AGV’s and 3.500 AGV control units throughout the world.

Jan 25, 2005 · achieved with the implementation of an Automated Guided Vehicle, AGV. In a traditional warehouse, human safety governs the productivity. With the help of intelligent computers, the AGV can safely achieve higher speeds. Precision turning allows it to accurately navigate in tight spaces. The AGV is highly flexible as a result of remote communication.

Feb 01, 2001 · Introduction. A material handling system occupies an important position to establish an autonomous decentralized manufacturing system (ADMS). Especially, an autoally guided vehicle (AGV) plays a central role in the intelligent material handling system. In order to drive the AGV autonomously in ADMS, two types of problems arise.

AGV, intelligent mobile robots. AGVs optimize your logistics performance by moving and storing loads safely in your factories and warehouses. Productivity gain. Cost reduction. Fast return on investment. Guaranteed safety of people, processes and loads. Optimal operation 24/7. Storage capacities optimization.

Feb 01, 2001 · A material handling system occupies an important position to establish an autonomous decentralized manufacturing system (ADMS). Especially, an autoally guided

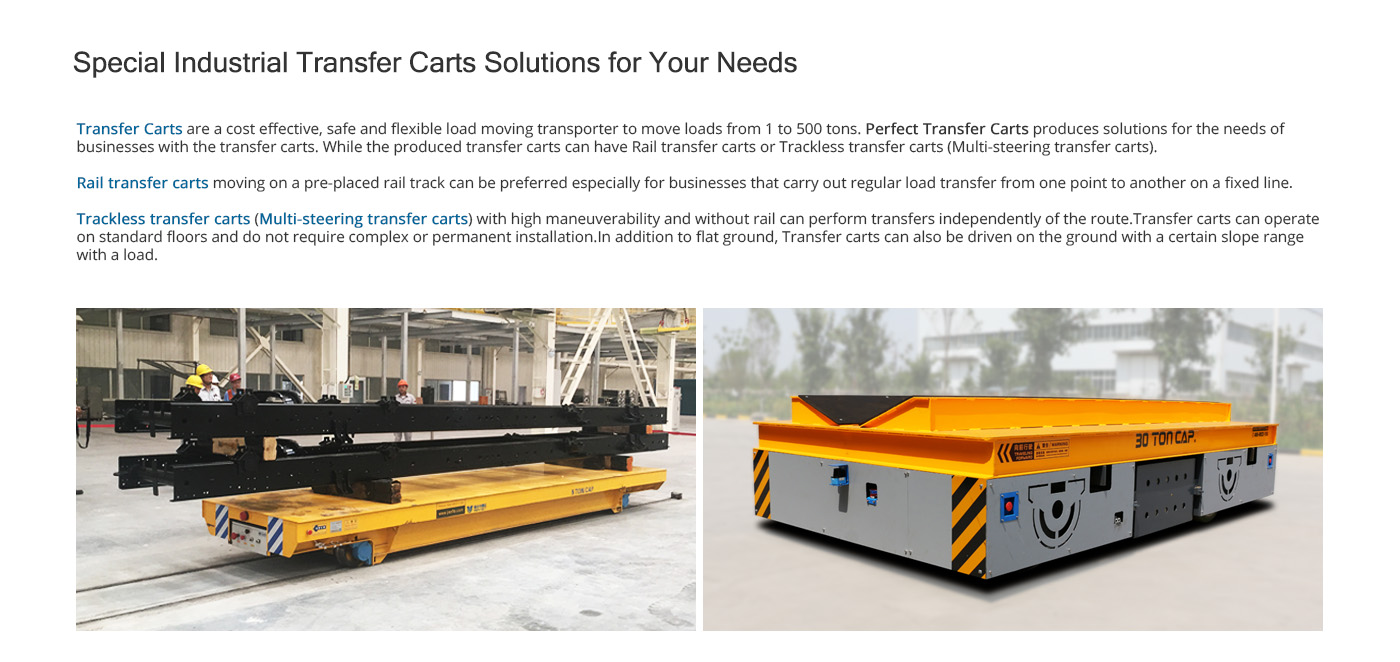

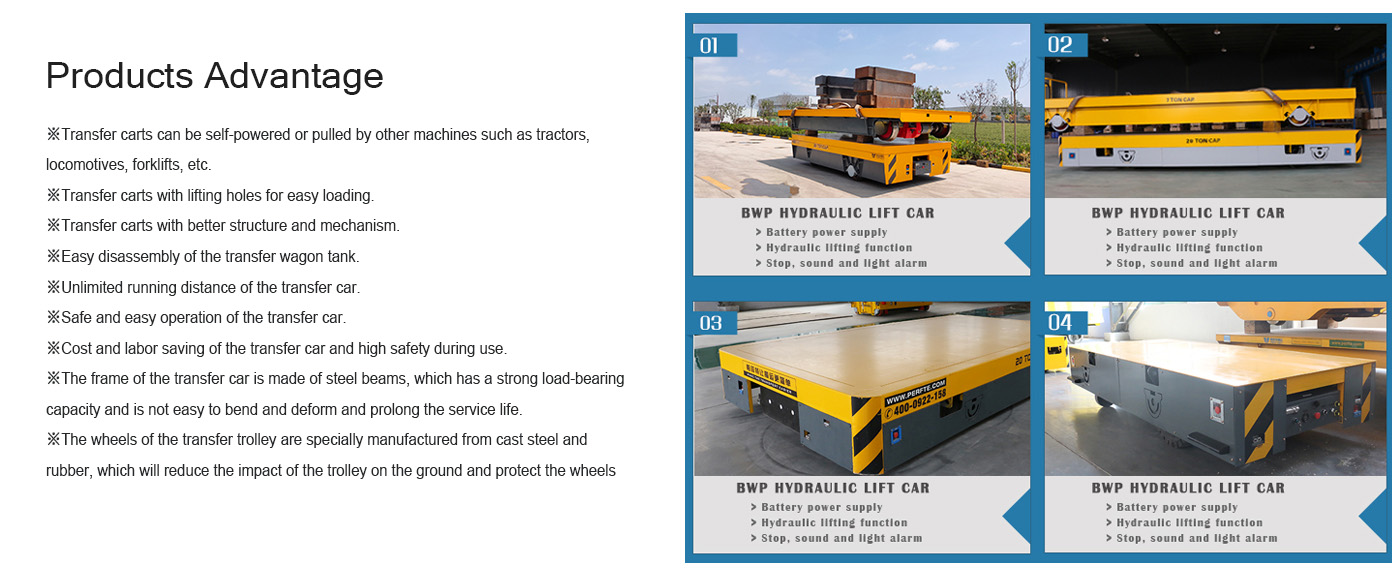

Traction AGV Load AGV Forklift AGV AGV + Carrier AGV + Vision / Manipulator Wheeled Inspection Robot. Intelligent Equipment. Intelligent Load Transfer Intelligent Welding Intelligent Stacker Intelligent Mask Production Line Intelligent

Mar 08, 2018 · Although AGV as an intelligent transportation device can not represent the entire intelligent logistics system, it is an indispensable role as an important link connecting intelligent production, intelligent factories, and intelligent logistics. Storage Industry. The earliest place for applying AGV to production was the warehousing industry.

Unlike traditional AGV, AMR has the functions of autonomous movement and intelligent obstacle avoidance. AMR does not need to lay fixed rails or magnetic strips. In this way, many troubles during deployment are saved, especially when the production process is changed, it is only necessary to rebuild the map or plan the route inside the robot

"/>

"/>

Otis Technology, a manufacturer of gun care systems for military applications, has decided to use a new generation of intelligent automated guided vehicles (AGVs) to support its Lean manufacturing strategies through an automated, but flexible, way to move materials around the factory floor in its Lyons Falls, NY production facility.

Jul 04, 2009 · Lin L., Shinn S. W., Gen M., Hwang H. (2006) Network model and effective evolutionary approach for AGV dispatching in manufacturing system. Journal of Intelligent Manufacturing 17: 465–477. Article Google Scholar Qiu L., Hsu W., Huang S., Wang H. (2002) Scheduling and routing algorithms for AGVs: A survey.

The eQart® is an autonomous and remote-controlled material handling cart. By using FlexQube building blocks and complementing them with digital modules such as motors, battery, control unit, and sensors, we can offer a flexible, affordable, and user-friendly concept. T he eQart® has a market-leading size flexibility from 910 x 840 mm up to 2510x 2510 mm, it can beCustom for

new energy. Astroime Company has realized the robot bolt fastening flexible manufacturing system, the AGV intelligent production line, the intelligent flexible grinding and polishing technology for thePerfect curved surface of wind turbine blades, and the autom

Oct 09, 2021 · One of the fresh materials is transported by accessing services of AGV to dominatingly provide for three stages: (1) intelligent logistics conveying equipment for weaving process and drawing fresh materials equipment from warehouse district through the AGV services; (2) fresh materials transported to auto feeding and unpacking area, the